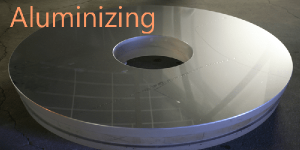

Aluminizing

Prominent Coating Apply for the Metals into a Procedure of Heat Treat – Aluminizing process

Warmth treatment shapes put incredible strain on the gear utilized in them. Specifically, the bushels utilized in heat treatment Company in the USA take a goliath level of prepare since high temperatures can cripple most metals with the target that irrefutable weight factors, for example, the breadth of held parts, have an expanded effect, Things to know and ask about Aluminizing.

This can to an astonishing degree decrease the obliging closeness of your flicker treat cases which impels essentially more extraordinary substitutions and higher working expenses.

By shot, even these metals will debilitate if appeared to specific conditions. Which is the reason a dash of Marlin’s customers asks: “is there another approach to manage supervise organize draw out the critical vicinity of a brightness treat case or plate?”

It is the clarification for the bushels and warmth treat plate confused need

Before we get into answers for warm treat wire holder/plate frustrations, it’s vital to know why these metal structures droop disagreeably.

The high temperatures of the splendor treat process can harm metal, making it more inclined to losing shape or breaking, yes. Unavoidably, worry from the inconceivability of held parts isn’t the vital wellspring of disappointment in these metal structures.

Other key clarifications behind disappointment in warm treat takes after include:

- Metal Dusting: In carburizing diagrams, certain metallic parts can pull back into metal powder at temperatures in the 800-1,650°F (430-900°C) zone in low-oxygen, high hydrocarbon (methane, propane, ethane, et cetera.) conditions. The iron composite in a metal shape can be over-sprinkled with carbon and continue with the change. This can cause embrittlement and loss of adaptability.

- Thermal Fatigue: Since a metal shape survived the brightness treat process doesn’t recommend that it’s still as solid as before it went in. Extravagant warming and cooling of metal structures can make a temperature inclination between inside obsession and outside shell of the metal—causing clear rates of improvement and weight among inside and external layers. After some time, the part starts to break under the underlined strain.

A foreseen structure for pulling in metal cleaning is to utilize a high-nickel blend, (for example, Inconel®). High nickel composites limit the carbon submersion impact of metal cleaning and can repudiate oxidation at high temperatures other than.

Regardless, a warm need remains an issue, paying little heed to for Inconel® holders and plate. In what inspiration driving requirement may you diffuse the effect of warm worries to accumulate the basic closeness of your brightness treat bushels?

One methodology is to apply a particular covering to your brilliance treat metal structures, at any rate, an empowering covering will do:

Know that Aluminizing Prolongs the life of warmth treat case

Coatings for warm treat holders must be particularly invulnerable to warm, so most polymer-based coatings are not fitting for this utilization. The reason is that most polymers have a softening point evaluated in the unquestionable degrees Fahrenheit, while a warm treat hypothesis can beat 500 to 2K°F.

One covering treatment routinely utilized for ensuring heat treat cases and the plate is aluminizing.

In some ways, this system takes in the wake of electroplating. Here, a blend of aluminum, halide salt, and a lethargic filler material is utilized to exchange aluminum particles onto the surface of the metal being secured. This impacts a watched aluminum oxide to layer for warm treat bushels that will survive high temperatures.

Aluminizing has been adequate used to upgrade the oxidation, utilize, and wear-catch properties of high-nickel amalgams, for example, Inconel® for warm treat shapes. The lion’s share of a satisfactorily sudden, a compartment that has been aluminized may need to experience a brightness treat process itself to recoup the properties of the substrate blend.

It’s basic to see that finally, even the hardest, most all-around amassed warm treat boxes will come up short. The weights included are essentially nonsensically unprecedented for any compartment, making it hard to altogether withstand all the strain until the whole of time.

Notwithstanding, by utilizing aluminizing to coat your flicker treat holders and revive their affirmation from oxidation, warm weight, and use, you can extend the principal closeness of your compartments to recommend change return on your theory.

Also know more about the Things worth knowing at knowandask